Grinding Ball Wear Rate Mining

Metallurgical Examination of Grinding Media Balls

Poor quality grinding balls influence the whole grinding system, including ball consumption, effectiveness of grinding and power consumption thus significantly impacting on the cost of comminution. High wear rates not only increase ball consumption rates but can also impact product quality and, in some cases, increase costs due to increased reagents and/or lower efficiency of .

Stainless steel grinding balls for mining / ball mill

Home; Grinding balls for mining suitable for all mill appliions. Grinding balls for mining are made from various metals such as steel, hard metal and, they are commonly manufactured from steel and steel alloys which have superior resistance to abrasion and low wear might be between 15 and 66 on the Rockwell Scale or between 85 to 105 on the Vickers hardness ...

grinding ball wear rate mining

· Grinding Media Wear Rate Calculation in Ball Mill. Table of ContentsData on Ball ChargesBall Mill Ball Wear ProjectionRecapitulation of Ball Wear FormulasPractical Appliion of Theoretical Conclusions In the previous discussion the fact was established that the work done by a ball when it strikes at the end of its parabolic path is proportional to its weight and velocity; then, since the ...

how to estimate the wear rate for Ball mill

· Re: how to estimate the wear rate for Ball mill. Ball wear can be measured by weighing an entire charge before and after grinding a known tonnage of materials. With new balls sample of given size can be weighed before and after grinding a given tonnage and, assuming uniform wear per unit of ball surface, the total charge wear can be estimated.

Industrial Solutions velix

The maximum wear rate on a tip liner is where the screw dips into the material flow. With conventional screw designs wear is directly related to material processing. Wear, loss of screw length, in a conventional design results in a larger nongrinding area at the bottom of the mill. So we challenged ourselves to develop a new tip liner concept. With our newly designed tip liner horizontal ...

Grinding media

Low wear rates. Industry: Mining. Coal grinding. Other wet appliions. Equipment: Ball mills. Tech Specs: Diameters: 100 > 13mm (4″ > ½"). Cr nominal %: 10 > 35. Key Benefits: Steady milling conditions due to low wear rate. Constant hardness of all grinding media for each alloy.

Cast High Chrome Balls

The chemistries have been designed for use in mining appliions to ensure optimal product performance. Molycop can supply product with chrome levels ranging from 10% – 30% based on your requirements. Primary/secondary ball milling: Cast High Chrome media with lower wear speed rates that offer a longer lasting product to liberate the desired minerals from crushed ore. Regrind/fine grinding ...

Tech Grinding Media

Our grinding media are used globally in mining, cement, power and chemical industries. ... Wear rate variation < 1% between balls: QUALITY ISO 9001:2008 SGS Certifiion: CORPORATE BROCHURE: PRODUCTION CONTACTS UNITED STATES OF AMERICA TECH GRINDING MEDIA INC., 8815 CONROY WINDERMERE ROAD, ORLANDO, FL, USA 32835 TEL: 647 400 2659 .

Virina Steel Grinding Balls

•VS grinding balls show a % decrease in wear rate –VS average wear rate g/t –Competitor average wear rate g/t . Virina Steel Grinding Balls Benefits •Reduced ball weight in mill •Extended ball life •Processing mill consumes less energy •Increased production •Reduced down time •Reduced labor •Increased profit

List Factors Affecting Grinding Ball / Media Wear Rate

· Relative Wear Rates of Various Diameter Grinding Balls. In order to determine the relative wear rates of several sizes of grinding balls, groups of 4, 3½, 3, and 2 in. balls were marked individually and were charged, all at the same time, into each of two production mills grinding copper ore. The remainder, and vast majority, of the ball charge consisted of 2 in. diam, and smaller, white ...

High Chromium Cast Balls

Higher hardness ¦ Lower wear rate Good toughness ¦ Less breakage "GUOYANG"CAST GRINDING BALLS are widely used in mining, power plant, cement and magnetic materials industries. In the using process, the surface hardness getting higher and the wear resistant getting strengthen, at the same time, the production capacity of ball mill getting improved. Diameter(mm) Φ10. Φ Φ15. Φ17 ...

Calculators

Grinding media wear rate. For monochamber mill. For 2 chambers mill. Payback, ROI and IRR. Mill's internals. Circuit modifiion . Mass balance. Open circuit. Filters sizing. Electroprecipitator. Grinding circuit cost. Grinding plant sizing. Closed circuit 1. Closed circuit 2. Closed circuit 3. Closed circuit 4. Closed circuit 5. Closed circuit 6. Bag reverse air. Bag pulse air. Roller ...

Grinding Ball Wear Rate Mining

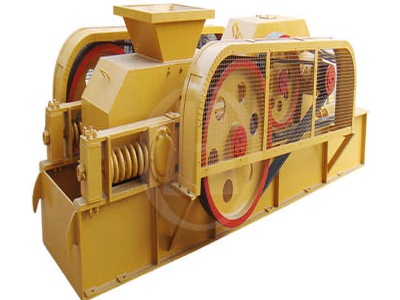

Grinding Ball For Mining Grinding Ball For Mining. Alibabacom offers 25196 grinding ball for mining products a wide variety of grinding ball for mining options are available to you such as material local service loion and applicable. China Unbreakable Wear Grinding Steel Ball For Mining

(Received: February 1, 2016; Accepted: November 4, 2016)

Journal of Mining and Metallurgy, 52 A (1) (2016) 1 10 #Corresponding author: A COMPARISON OF WEAR RATES OF BALL MILL GRINDING MEDIA A. Jankovic#, T. Wills, S. Dikmen Metso Process Technology and Innovation, Brisbane, Australia Queensland Centre for Advanced Technologies, 1 Technology Court, Pullenvale, QLD 4069 Australia .

Grinding Ball_Tangshan Fengrun Shougang Metallurgy And ...

The product's property will be high in hardness, good in wearresistance, low in breakage rate after isothermal quenching treatment. As one kind of grinding media, forged steel ball was widely used in ball mill and semiauto grinding mill system of mines, building materials and chemical industries.

Latest Posts

- خام البوكسيت كازاخستان سحق عملية

- مطحنة كسارات الذهب مصنع للبيع

- استهلاك الوقود كسارة الحصى

- كسارة الحجر في المملكة العربية السعودية صورة

- تستخدم كسارة الصخور المتنقلة في مصر

- الزاوي رئيس طحن صغيرة

- معيار مصر للكسارات المنتجة

- مصنع طحن الأسمنت الصين

- سعر محجر رمل السيليكا العالي في عمان

- ذروة سحق معدات عمان

- الذهب النقال سحق المعدات

- كسارة الصخور زامبا

- أنواع السيور الناقلة

- البدء السلطة لمطحنة الكرة

- زينيث كسارة الفك المحمولة للبيع

- Grinding Process Traverse

- Equipment Used To Extract Fine Sand From Sand Washing Plant

- Boseto Copper Project Map

- Bengal Emta Coal Mining Properties

- Magnesite Mobile Stone Crusher Supplier

- Knife Grinder Protected

- E 300 Jaw Crusher

- Vertical Roller Mill Cement Industry Operations

- Mobile Crusher Brochure

- Impacts Of Processing Manganese On The Earth

- Impact Crusher Mendoza

- Granite Concrete Crushing

- Used Concrete Crushers Price In Uk

- Pujiang Mesin Grinding Crystal Trophy

- Mini Micronizing Mill Powder Micronizing Mill Machine Mini Stone Mill