Grinding Media Working Principle

Ball Mill

Ball mills. The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1– times the shell diameter (Figure ). The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

Cement mill notebook

· The optimal operating speed depends mainly on filling degree, grinding media size and type of liners. Critical Speed: The critical speed of a tube mill is that speed of rotation at which the centrifugal power neutralizes the force of gravity which influences the grinding balls, the grinding balls don't fall and therefore don't perform grinding work. Or to make the definition more easy ...

Bead Mill maker Ashizawa Finetech Ltd.

Bead mills are grinding and dispersing machines designed to grind and/or disperse particles down to the micro and nano scales. Beads (grinding media) inside the grinding chamber are agitated by rotating the shaft and the particles are ground and/or dispersed by the collision and shear force of the beads. The outlet of the grinding chamber has a filtering structure to separate beads from ...

How Do Wind Turbines Work? | Department of Energy

Wind turbines work on a simple principle: instead of using electricity to make wind—like a fan—wind turbines use wind to make electricity. Wind turns the propellerlike blades of a turbine around a rotor, which spins a generator, which creates electricity. Explore a Wind Turbine To see how a wind turbine works, click on the image for a demonstration. Types of Wind Turbines > Sizes of Wind ...

3M Roloc Appliion Guide

Grinding and stock removal 11 Positioning 12 ™3M Cubitron ... Works for lighter appliions than 984F due to the blend of 3M ™ PrecisionShaped Ceramic Grain and conventional grain Advanced Series Products: 3M™ Roloc™ Fibre Disc 782C 3M™ PrecisionShaped Ceramic Grain Mild steel Small weld removal, blending, finishing, refining, deburring, small beveling 3M ™ Roloc Fibre Disc 787C ...

Planetary Mono Mill PULVERISETTE 6 classic line ...

WORKING PRINCIPLE. Comminution according to the Planetary Principle. The comminution of the material to be ground takes place primarily through the highenergy impact of grinding balls. To achieve this, the grinding bowl, containing the material to be ground and grinding balls, rotates around its own axis on a main disk whilst rotating rapidly in the opposite direction. At a certain speed, the ...

Grinding and Polishing

GRINDING removes saw marks and levels and cleans the specimen surface. Polishing removes the artifacts of grinding but very little stock. Grinding uses fixed abrasives—the abrasive particles are bonded to the paper or platen—for fast stock removal. Polishing uses free abrasives on a cloth; that is, the abrasive particles are suspended in a lubricant and can roll or slide across the cloth ...

Grinding and Finishing

Grinding – Ex. 11 • You are grinding a steel, which has a specific grinding energy (u) of 35 Ws/mm3. • The grinding wheel rotates at 3600 rpm, has a diameter (D) of 150 mm, thickness (b) of 25 mm, and (c) 5 grains per mm2. The motor has a power of 2 kW. • The work piece moves (v) at m/min. The chip thickness ratio (r) is 10.

Grinding Wheels Types, Material Specifiions ...

· Grinding wheel specifiion depends on these aspects such as. Material Removal, Intermediate Cut And Finish, Finishing Cutting, Corner Holding, Cleaning, Cylindrical, Dry Grinding, Form Grinding Etc. Bond type. It is formed in between the abrasive grains and the grains of the metal substrate. It can be of resin/plastic, rubber, shellac, silie, oxychloride, vitrified etc. Mounting: The ...

Your Digestive System How it Works | NIDDK

Your hormones and nerves work together to help control the digestive process. Signals flow within your GI tract and back and forth from your GI tract to your brain. Hormones. Cells lining your stomach and small intestine make and release hormones that control how your digestive system works. These hormones tell your body when to make digestive juices and send signals to your brain that you are ...

AMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator ...

The main costs for grinding are energy, liners and grinding media. They are different for different mill types. For tumbling mills: Diagram of cost breakdown by mill type [image: (135617)] Basic Mill Linings. Use rubber linings wherever possible due to lifetime, low weight, easy to install and noise dampening. When appliion is getting tougher use steelcapped rubber, still easier to ...

Catalytic Converter: How It Works | Science Garage

Exhaust has a lot to do with performance. Catbacks, Mufflers and resonators get all the attention, but the Catalytic Converter is super cool too! It's an ...

GRINDING MACHINES

Swing in work head (diameter) 4 l/2inch diameter. Nonspecialized cylindrical grinding machines in the Army maintenance system include the tool post grinding machine and the versa mil attachment. Tool Post Grinding Machine The tool post grinding machine, see Figure 55, is a machine tool attachment designed to mount to the tool post of engine ...

Rod Mills, How Do They Work?

Rod Mills, How Do They Work? Rod mills are very similar to ball mills, except they use long rods for grinding media. The rods grind the ore by tumbling within the the mill, similar to the grinding balls in a ball mill. To prevent the conditions leading to rod charge tangling, the length to diameter ratio is maintained at to

Ball Mills | Air Classifiion | United States

Ball Mills | Air Classifiion | United States. RSG Inc, loed in Sylacauga, Alabama specializes in fine powder technology. The company manufactures air classifiers, ball mills and stirred media mills for the production of fine, superfine and ultrafine powders for the mineral, mining, cement, lime, metal powder and chemical industries.

Practical Roll Techniques

· Consistent grinding and balancing of rolls is necessary for efficient operation and optimum paper quality. As an integral part of a modern roll maintenance program, roll grinding and balancing uses machinery with accurate inspection and measurement equipment. This paper provides practical tips on roll inspections, balancing, grinding and grooving. In addition, we discuss proper roll handling ...

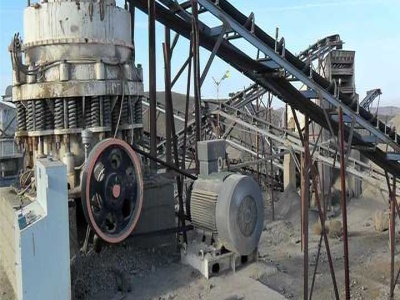

grinding media working principle

grinding media working principle ; Latest Projects. K Series Mobile Crushing Plant. K Series Portable Crusher Plant, also known as K Series Portable Crusher, Crawler Mobile Crusher. Crawler Mobile Crusher is a fully hydraulic tracktype mobile crusher developed and completed in .

milling principle

The working principle is that when the cylinder is rotated, the grinding body (ball) and the object to be polished (material) installed in the cylinder are rotated by the cylinder under the action of friction and centrifugal force. At a certain height, it will automatically fall and impact and grind the material in the cylinder to grind the material . principle and working of milling machine ...

Latest Posts

- محاجر التعدين في مصر

- مصنعي محطات معالجة الفحم

- خط الجبس تجهيز مسحوق

- الذهب واستخراج الماس المعدات الموردين

- مطحنة كرات كربونات الكالسيوم في اليمن

- أسعار المطاحن العمودية

- بيع كسارة فكية مضادة للجرانيت

- موردي مصانع معالجة الأحجار من المكسيك

- المورد من كسارة ميلر

- كسارات فولتاس فى مصر

- كيفية عمل التوازن الحراري للطاحونة في محطة توليد الكهرباء

- مصنع مطحنة الذهب الرطب الذهب عموم بأسعار تنافسية

- الكسارات العالي

- تشغيل الكسارة 150 مم يكلف اليورو

- مصنعي مكثفات التعدين في مصر

- Ball Mill To Grind Coalball Grinding Machine To Grind Coal Zimbabwe

- Machine For Transporting Gravel

- Crusher Zone In Karnataa

- Tyof Ball Mill Cylinder Machine

- Manual Sanding Machine

- Pressive Strength Of Concrete Mortar

- The Hammer Crusher Baru

- Crusher Used Jaw Rolelr Crusher Price

- Copper Por Le Crusher

- And Fabrication Of Crusher

- Gambar Raymond Mill R

- Crushre And Price

- Total De Planta De Trituracion De Ghana

- Iron Ore Finely Ground

- Granitestone Crusher S A